"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

our machines aren’t slowing you down—your systems are.

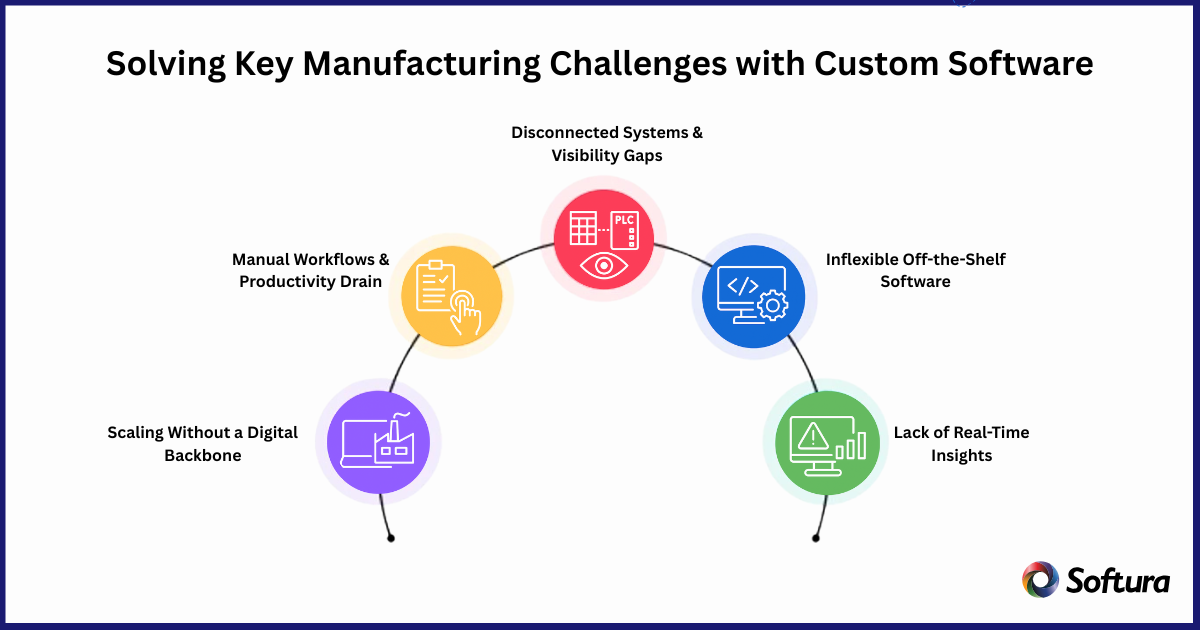

As manufacturing advances, many companies still rely on outdated, disconnected tools and rigid off-the-shelf software that create inefficiencies, delays, and data silos. The problem is not a lack of technology; it is a lack of solutions designed to fit how your operations truly work.

Custom software application development addresses this gap by aligning technology with your processes, people, and production goals. It streamlines workflows, integrates systems, and delivers real-time visibility where it matters most.

This blog explores five major manufacturing challenges and how custom-built solutions can solve them with precision. For a deeper dive into the broader benefits.

"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

Manufacturers often operate with a mix of legacy ERP, MES, spreadsheets, and PLCs that fail to communicate. This results in fragmented data, process delays, and limited operational visibility.

Custom software application development addresses this by integrating legacy systems, creating secure data pipelines, and enabling real-time insights through role-based dashboards.

For example, one automotive supplier unified its MES, warehouse, and finance systems using a custom integration layer reducing reconciliation time by 70 percent and improving inventory visibility across all plants.

Despite investments in automation, many critical workflows from quality inspections to shift handovers, still rely on manual processes. These tasks consume valuable time, introduce inconsistency, and reduce traceability.

Custom software application development eliminates this burden through tailored workflow automation. Whether automating QA steps, approval chains, or digital work instructions, custom solutions mirror your specific operational flow rather than forcing a one-size-fits-all approach.

A mid-sized electronics manufacturer replaced its paper-based QA checklists with a custom mobile solution. Operator inputs, shift logs, and inspection results now sync automatically with centralized dashboards, reducing order-to-ship cycle times by 30 percent and giving supervisors full floor-level visibility.

In high-throughput environments, delayed information is a competitive liability. Relying on historical reports or siloed data limits a team’s ability to intervene proactively or optimize in real time.

Custom software application development enables manufacturers to build real-time intelligence into their daily operations. By connecting IoT sensors, PLCs, and enterprise systems into one unified platform, decision-makers get live insights across machines, lines, and facilities.

A precision parts manufacturer implemented edge-enabled dashboards to monitor real-time output. When production dipped below thresholds, alerts were triggered instantly, enabling mid-shift corrections and cutting unplanned downtime by 22 percent within weeks.

Off-the-shelf software often becomes a bottleneck when business models evolve, or compliance demands shift. Customizing these platforms is costly, slow, and rarely aligned with production speed.

Custom software application development provides flexibility from day one. Modular design, configurable rules engines, and scalable architecture allow systems to evolve without disruption. Whether introducing a new product line, adapting to a new regulatory requirement, or adjusting the workflow, your software should keep pace.

A consumer goods manufacturer used a configurable platform to introduce new QC metrics across multiple production lines. Rather than waiting months for ERP updates, they deployed changes in days, maintaining compliance while keeping production uninterrupted.

Expansion exposes gaps. As manufacturers onboard new sites, suppliers, or automation technologies, disconnected systems make oversight harder, increase compliance risks, and delay onboarding.

Custom software application development gives organizations a centralized, extensible foundation for scaling intelligently. Whether managing multi-plant production, supply chain traceability, or distributed edge devices, custom solutions ensure operational consistency without sacrificing flexibility.

One medical device company deployed a custom-built platform to onboard three suppliers in under 30 days. The solution integrated documentation workflows, automated compliance checks, and delivered plant-level visibility without disrupting existing systems.

Custom software application development is more than a technical solution; it is a business strategy rooted in operational intelligence.

Because these solutions are built around your actual production environment, they improve more than just efficiency. They elevate transparency, empower frontline teams with real-time visibility, and equip leaders with reliable, actionable insights to drive performance forward.

Off-the-shelf platforms require your business to adapt to their logic. In contrast, custom-built applications are designed to support your unique processes, systems, and goals. This allows manufacturers to eliminate workarounds, reduce delays, and create natural workflows across departments and sites.

Custom software also enables better change management. When processes evolve or scale, modular architecture and API-first design ensure your systems can adapt without requiring major overhauls or costly vendor delays.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Manufacturing success today demands more than operational excellence; it demands technological precision. C-level leaders are not asking for more features; they are asking for fewer bottlenecks, faster decisions, and systems that support growth. Custom software application development delivers exactly that. It is not a patch. It is a platform for long-term competitiveness. When your software fits your business, your business runs smarter.

If your current systems limit efficiency or scalability, connect with our experts to explore a custom software solution built around your plant operations.

Ready to Solve Your Manufacturing Challenges?

Let Softura show you how custom software application development can streamline operations, reduce downtime, and power smart growth.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Custom software is designed around your specific operations, roles, and workflows. Off-the-shelf software offers generic functionality that often requires compromises. Custom solutions align directly with how you manufacture, integrate, and grow.

Not at all. While larger companies often need scale, mid-sized manufacturers benefit significantly from automation, reduced downtime, and process visibility that off-the-shelf tools may not provide.

Timelines vary based on scope, but many solutions can be built and deployed in stages, starting with core functionality within weeks, followed by modular enhancements.

Yes. Custom solutions are designed to integrate with your ERP, MES, PLCs, and even older legacy equipment, ensuring continuity without requiring complete system overhauls.