"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

From vivid real-life applications to tackling the hurdles of AI integration, this blog uncovers the futuristic landscape of manufacturing transformed by AI.

Plus, don't miss out on our exclusive giveaway: a comprehensive 50-Point Checklist for seamlessly integrating Generative AI into your manufacturing processes, setting the stage for efficiency and creativity.

Let's get started!

It's not just waves that generative AI makes; it presents a new ocean of possibilities. Think about this: it's not just a tool but now the brains behind operations, making things run more smoothly, better, and with a lot more new ideas.

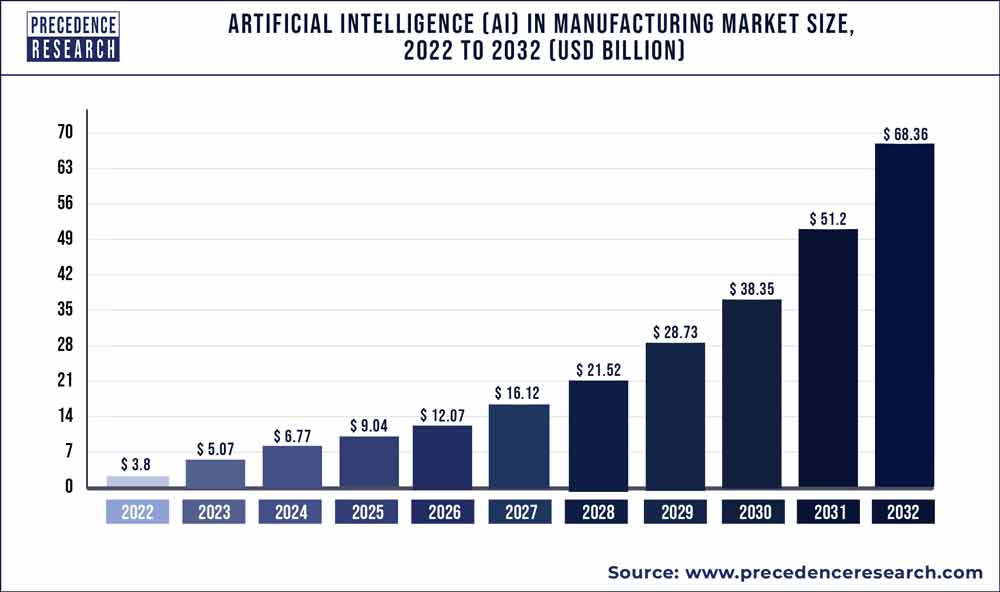

Now for the really cool part: the market for AI in production is growing like never before and will hit an amazing USD 68.36 billion by 2032. From 2024 on, the rate of growth will be 33.5% per year.

The reason behind such staggering figures is that using generative AI as a co-pilot for collaboration is like mixing machine speed and human imagination, which can surely take us miles ahead of our competitors and leap beyond current technological advancements.

If you’re ready to join the wave, let’s learn more about how generative AI actually functions in a manufacturing space as collaborative co-pilots.

"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

Generative AI is one of the most exciting developments in industry. We'll be talking about how it's not taking over jobs but rather making the human workforce more productive. Imagine having a smart, active force booster by your side. That's Generative AI.

The goal is to improve people's skills, not replace them, by adding a little AI magic to everyday jobs.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Generative AI is like high-tech gear that you can wear instead of giving robots control. This technology is changing the way we work by taking over boring and hard physical jobs. This lets people focus on what they do best: come up with new ideas, plan strategies, and make things.

Source: Markets and Markets

Let's get down to business with some real-life cases.

Imagine generative AI systems that are smart enough to know when technology will break down before it does. This would cut down on downtime and save the day.

Or, think about AI partners working with humans on the production line. They would not only do what they are told, but they would also learn and improve processes to make them safer and more efficient.

Another area where Generative AI really shines is quality control. It uses high-tech cameras and sensors to find flaws with an amazing accuracy. This technology doesn't just keep standards high; it's an engine that keeps learning and improving the production process all the time.

Customization? That is also taken care of by generative AI. It's letting companies make goods that exactly fit the needs of each customer. And it’s being done at speeds and on scales that were previously unthinkable. This is completely re-defining the idea of personalized production.

Siemens, a renowned industrial giant, is riding the wave of GenAI innovation by adding it to its factory heartbeat. When it comes to how we think about production in the 21st century, Siemens is ahead of the curve thanks to its focus on digital twins and AI-driven data.

Digital twins are virtual copies of real things. Siemens can practice and improve industrial processes in the digital world before they are used in real life.

Cool, right?

“Powerful, advanced artificial intelligence is emerging as one of the most important technologies for digital transformation,”

- said Cedrik Neike, Member of the Managing Board of Siemens AG.

But it gets even more interesting when Generative AI is added to these digital twins. They stop being just models and become real things. They work together with human experts and offer ideas and thoughts that were only seen in science fiction in the past.

For example, Generative AI's ability to quickly process large amounts of data lets Siemens predict how much machinery will wear out and plan maintenance in a way that keeps the production line running easily without any sudden stops. As a result? A big increase in productivity and a decrease in downtime. All because AI and people work together so well.

And Siemens doesn't stop at repairs.

The company's use of AI tools for quality control is another great example of how humans and AI can work together. It is possible for human inspectors to miss some flaws, but these tools help them find them. This protects Siemens' image for high quality without slowing down production.

There are some things that can go wrong when you try to use AI in industry. There are some problems to solve, but that's part of the fun of coming up with new ideas, right? Let's talk about how to deal with these issues.

There are many speed bumps and detours on the way to AI usage, so you need a plan that is both smart and flexible. The good news is that those problems start to look more like stepping stones when you have the right plan.

We've made a clear, complete 50-Point Checklist to help you with that. It will help you through all the tricky parts of adding Generative AI to your manufacturing world.

This list is full of clear, doable steps that will help you make those problems a thing of the past and use the full power of Generative AI in manufacturing operations, whether you're just starting out with AI or want to step up your game.

There are some things that can go wrong when you try to use AI in industry. There are some problems to solve, but that's part of the fun of coming up with new ideas, right? Let's talk about how to deal with these issues.

Download Now

Download NowWe are now at the point where convention and innovation meet, looking ahead to the way that Generative AI is leading the way in manufacturing. We have come a long way, but as we have seen, accepting AI doesn't mean giving up control.

Instead, it means working with a strong partner that builds on our strengths, inspires imagination, and pushes the limits of what's possible.

As we reflect on our progress toward the future, Softura is excited to share the insights and highlights from our recent webinar, 'Beyond Manufacturing Automation: The Co-Pilot Model in AI, IIoT, and Robotics.' If you missed the live session or wish to revisit the wealth of knowledge shared, the full recording is now available on YouTube,

Have questions or looking to integrate AI into your manufacturing operations?

Schedule a consultation session with our AI specialists. Whether at the beginning of your AI journey or looking to scale existing initiatives, our experts can provide tailored guidance to meet your specific needs.