"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

Logistics leaders rarely struggle to explain why change is needed.

They struggle to prove what it returns.

In most organizations, logistics already carries a reputation. It is the part of the business that absorbs every disruption, every customer promise, every supplier delay, and every operational surprise. It is also one of the few functions where small inefficiencies multiply fast.

That is why Logistics Software Development Services are no longer just an IT decision. They are a profit decision.

Yet many companies still evaluate logistics software the wrong way.

But ROI in logistics does not come from software itself. ROI comes from what the software removes: manual work, missed scans, late loads, idle trucks, over ordering, claim disputes, and operational blind spots.

This blog breaks down the real ROI of Logistics Software Development Services, backed by practical use cases and executive level insights.

Most C level leaders agree on one thing.

Logistics is expensive.

But many cannot see where the expense is hiding.

That is because logistics cost is rarely one clean line item.

It is scattered across:

Now add a second layer.

Many of the biggest logistics losses do not show up as “losses.” They show up as:

In executive reviews, these costs are often treated as the “price of doing business.”

That mindset is where ROI dies.

Because logistics inefficiency is not a cost of doing business.

It is a cost of doing business with the wrong systems.

"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

There is a common misconception.

Logistics software development is often assumed to mean building a full Transportation Management System or Warehouse Management System from scratch.

That is not the reality for most modern businesses.

Today, Logistics Software Development Services typically cover:

The goal is not to replace everything.

The goal is to remove friction between systems and people.

When friction is removed, cost drops and service improves.

That is the ROI.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

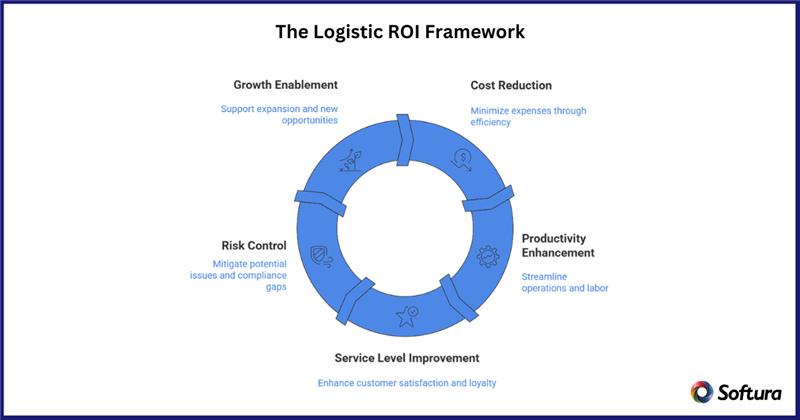

Logistics ROI is best measured across five value zones.

1) Cost Reduction

This is the most visible ROI and the easiest to track.

Cost reduction comes from:

2) Productivity and Labor Efficiency

In logistics, productivity is not about working harder.

It is about removing tasks that should not exist.

Examples include:

3) Service Level and Customer Experience

This is where ROI becomes strategic.

Better logistics software improves:

In many industries, service level is the difference between renewal and churn.

4) Risk and Compliance Control

Executives rarely put “risk reduction” on an ROI spreadsheet.

But logistics is full of risk:

Software reduces risk by enforcing process.

5) Growth Enablement

This is the most overlooked ROI.

Logistics software enables growth by making scaling possible without scaling chaos.

It supports:

When systems do not scale, growth turns into margin loss.

Many logistics teams track operational KPIs.

But executives care about KPIs that connect to business value.

Here are the metrics that consistently show ROI in board level reviews.

Transportation and Fleet Metrics

Warehouse Metrics

Customer and Financial Metrics

If a logistics software project cannot tie itself to at least three of these metrics, it is not ready.

In many mid market and enterprise companies, shipment tracking still looks like this.

What the Software Does

A custom shipment visibility layer connects:

Then it pushes updates to:

Where the ROI Comes From

The biggest returns come from:

Executive Insight

Many COOs describe this as “protecting margin.”

Because late deliveries are not just service failures.

They create:

Visibility software pays back by reducing surprise.

Dispatch is one of the most underestimated value areas.

In many fleets, dispatch still depends on:

That works until it does not.

When a dispatcher is out, performance drops.

When volume spikes, the team breaks.

What the Software Does

Custom dispatch software typically includes:

Where the ROI Comes From

Executive Insight

From a CFO lens, dispatch software is one of the few investments that improves both cost and capacity.

It helps the business handle more volume with the same fleet.

That is direct ROI.

Warehouses are often where ROI shows up the fastest.

Why.

Because the work is repetitive and measurable.

And because mistakes are expensive.

A mis pick is not a small error.

It triggers:

What the Software Does

Custom warehouse mobility solutions include:

Where the ROI Comes From

Executive Insight

Warehouse leaders often say the same thing.

The best ROI is not in speed.

It is in eliminating rework.

Because rework is the most expensive type of work.

Detention is a silent killer.

It damages:

Many companies accept detention as unavoidable.

It is not.

What the Software Does

A dock and appointment scheduling system can:

Where the ROI Comes From

Executive Insight

From a COO perspective, detention is not a carrier issue.

It is a planning issue.

Software fixes planning.

Claims are one of the most frustrating logistics problems.

Not because claims are complex.

But because the process is slow.

A typical claims cycle includes:

That delay is costly.

It creates write offs.

What the Software Does

A modern POD and claims workflow can:

Where the ROI Comes From

Executive Insight

CFOs tend to like this use case.

Because it directly improves cash recovery.

Most ROI conversations focus on cost and service.

But the most underrated benefit of logistics software is speed of decision.

When data is scattered across systems, decisions slow down.

When decisions slow down, teams compensate with:

That compensation is expensive.

A strong logistics software foundation reduces the time between:

That time reduction is not just operational.

It is financial.

A practical rule exists.

If the software is a commodity, buy it.

If the software is a competitive advantage, build it.

Most executives do not want custom development for the sake of it.

They want it where it matters.

Custom development makes sense when:

Buying makes sense when:

Smart companies choose partners who understand both technology and business reality.

Softura works with organizations that want control, transparency, and long term value from software outsourcing services. The focus stays on alignment, quality, and measurable outcomes.

Rather than offering generic delivery models, engagement structures are shaped around business goals, risk tolerance, and growth plans.

Most logistics software ROI does not come from one big platform.

It comes from connecting platforms.

In real operations, there are multiple systems:

When these systems do not talk, humans become the integration layer.

Humans are expensive.

And humans make errors.

Custom integrations remove that cost.

This is why many leaders now treat integration work as a core part of Logistics Software Development Services.

Executives often ask a fair question.

How can ROI be estimated before the software exists.

The answer is simple.

Start with operational friction.

Then translate friction into cost.

Step 1: Map the Most Expensive Workflows

Look for processes with:

Step 2: Measure Current State Cost

This includes:

Step 3: Set a Conservative Improvement Target

Not 80%.

Start with 10% to 25%.

Step 4: Connect to Business Outcomes

Tie it to:

This approach creates a defensible ROI story.

Many logistics software projects fail.

Not because the idea is wrong.

Because the execution is sloppy.

The most common ROI killers include:

A logistics system is only as strong as the data feeding it.

That truth should be uncomfortable.

But it is also why the best projects start with data cleanup.

Different executives care about different ROI outcomes.

What COOs Usually Prioritize

COOs want:

What CFOs Usually Prioritize

CFOs want:

What CIOs Usually Prioritize

CIOs want:

What CEOs Usually Prioritize

CEOs want:

The strongest logistics software ROI story is the one that speaks to all four.

Most leaders do not need a three year program.

They need a clear path.

The highest ROI roadmap usually follows this order.

Phase 1: Visibility and Data Foundation

Start with:

Phase 2: Workflow Automation

Then focus on:

Phase 3: Optimization

After stability comes:

Phase 4: Scale and Expansion

Finally:

This approach prevents chaos.

And it protects ROI.

This is where many companies make expensive mistakes.

A logistics partner is not just a dev team.

They are a risk manager.

The right partner will:

The wrong partner will:

A simple test exists.

If a partner cannot explain ROI in operational terms, they are not ready.

Logistics Software Development Services pay back when they remove that compensation.

If logistics costs are rising, exceptions are constant, or visibility still depends on emails and spreadsheets, it is time to explore a practical roadmap.

Talk to Softura about logistics software development services built for measurable ROI.