"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

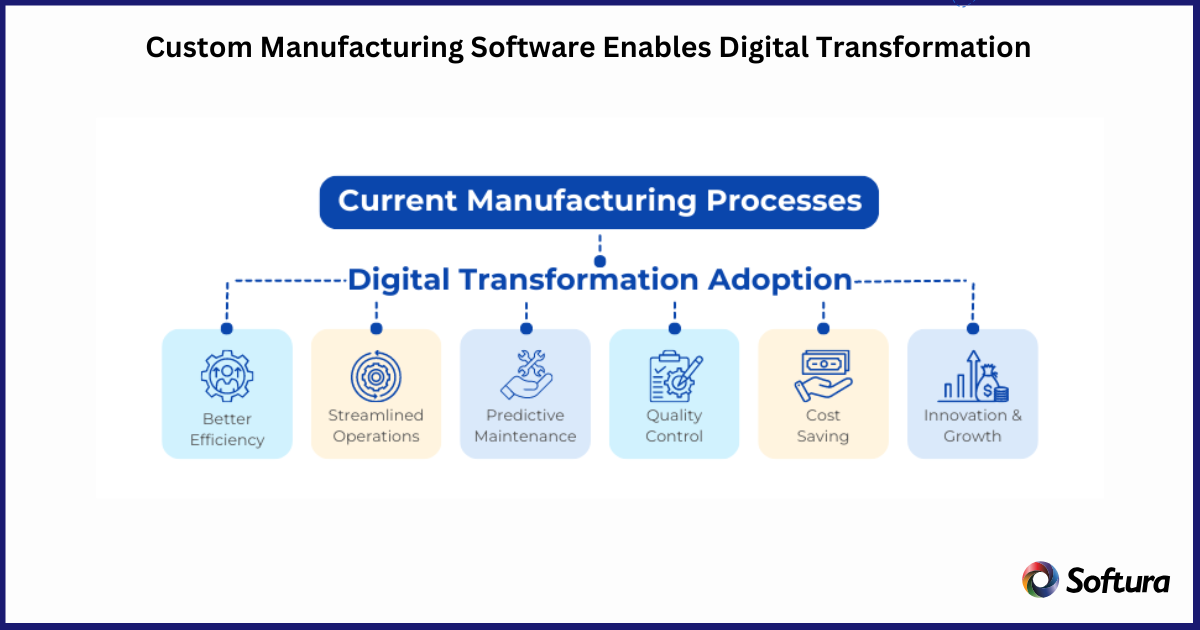

Digital transformation is no longer just a buzzword in the manufacturing sector, it's a business imperative. But while many factories rush to modernize with off-the-shelf solutions, one-size-fits-all software often fails to address the unique needs of complex manufacturing environments. That’s where custom manufacturing software development comes in. Tailored solutions do more than just digitize existing processes.

They drive operational efficiency, give real-time insights, and lay the groundwork for smart, connected factories. In this blog, we’ll explore how custom-built software is helping manufacturers fast-track their digital transformation journeys on the factory floor.

The manufacturing industry is evolving rapidly due to factors like global competition, supply chain disruption, and rising customer expectations for personalization. This shift demands:

To meet these goals, manufacturers are increasingly turning to digital tools powered by IoT, AI, and big data. But implementing these technologies effectively requires a solid digital foundation.

"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

Custom manufacturing software development involves designing and building tailored digital solutions that address the specific needs of a manufacturing operation. Unlike off-the-shelf tools, these systems are purpose-built to align with your workflows, equipment, data models, and business goals.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Accelerate Your Digital Transformation with Custom Manufacturing Software

Unify your operations, harness real-time data, and scale smarter with solutions tailored to your factory’s unique workflows and goals.

Many traditional factories operate with outdated, disconnected systems. Engineers might use spreadsheets for production planning, while quality teams rely on manual checklists. This fragmentation slows down decision-making and creates data blind spots.

Custom software integrates disparate systems into a unified digital ecosystem. This leads to,

As a result, manufacturers can identify bottlenecks, minimize downtime, and respond to issues proactively.

One of the biggest advantages of manufacturing software development is its ability to collect and process real-time data from the shop floor.

Using sensors, IoT devices, and machine integrations, custom applications can,

This allows teams to shift from reactive to data-driven operations, where decisions are backed by insights rather than assumptions.

Unplanned downtime can be costly, both in terms of lost output and delayed delivery commitments. Custom software solutions integrated with IoT sensors and AI models can detect early signs of equipment failure.

As manufacturers move toward mass customization, the need for flexible systems grows. Off-the-shelf software may not accommodate changes in demand, material availability, or customer preferences.

Custom-built systems powered by AI in manufacturing can,

This adaptability is key to staying competitive in fast-changing markets.

Quality assurance is not just about detecting defects, it’s about preventing them altogether.

Custom software manufacturing can embed quality checks into every step of the production process. Whether it's by integrating machine vision for inspections or auto-flagging out-of-tolerance data points, this proactive approach reduces waste and improves product consistency.

Digital transformation isn’t just about machines—it’s also about empowering people. Custom mobile apps, real-time alerts, and intuitive dashboards allow workers and supervisors to respond quickly to changing conditions on the floor.

Benefits include,

Generic software often becomes a limitation as your factory grows or adopts new processes. Custom manufacturing software, however, is built with scalability in mind.

You can,

This flexibility ensures your digital strategy can evolve along with your business goals.

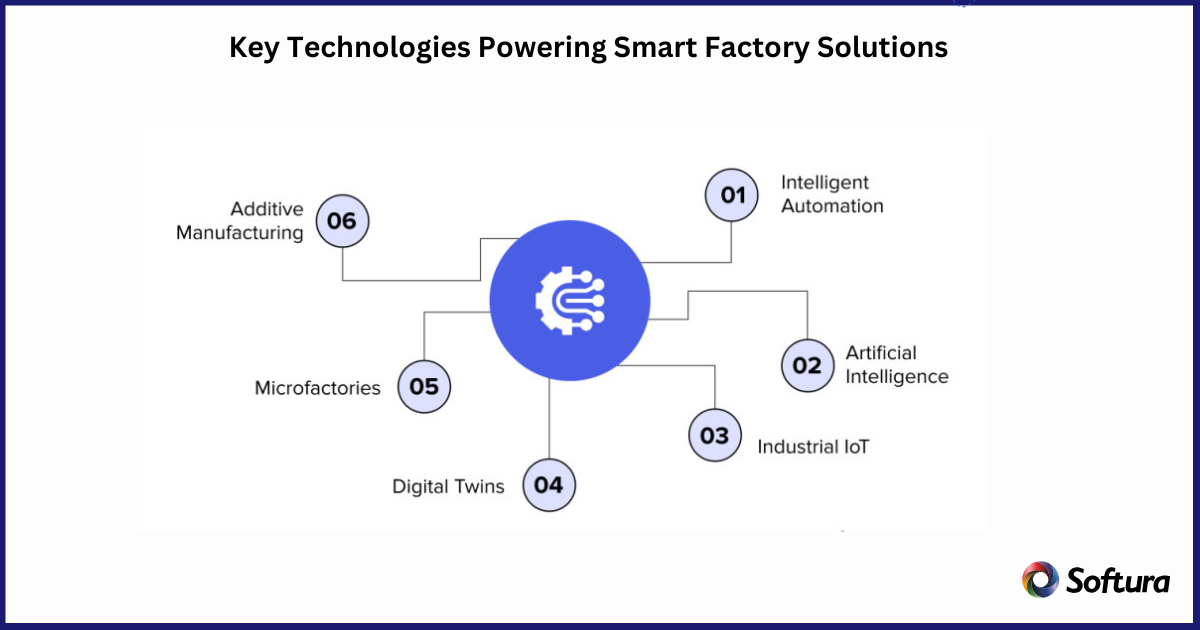

Custom manufacturing software leverages several emerging technologies to accelerate transformation:

By implanting these capabilities, custom-built software transforms traditional factories into smart, data-driven environments.

Let’s look at how real factories can apply tailored solutions,

Each of these examples shows how custom software directly supports operational goals in ways that generic solutions simply can’t.

Manufacturing is moving into a new era—one where flexibility, intelligence, and speed determine success. Custom manufacturing software development is the foundation that allows companies to adopt smart technologies without disrupting existing workflows.

While off-the-shelf tools may seem faster to deploy, their limitations often surface quickly. By investing in solutions designed for your unique challenges, you set your organization up for long-term success in a digitally transformed future.

Whether you’re just starting your digital journey or looking to optimize existing systems, custom software could be the key to experiencing your factory’s full potential.

Partnering with the right software development team like Softura ensures your technology aligns with your goals. From consultation to implementation, experienced developers can help you navigate the path to transformation with confidence.

Get Started with Our Custom Manufacturing Software Development Services

Build the Factory of the Future with Softura

Leverage IoT, AI, and cloud-powered custom software to transform your production floor into a connected, intelligent, and agile ecosystem.