"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

As manufacturing plants push for leaner operations, digital visibility, and faster production cycles, the software that powers these goals is no longer a back-office tool—it’s a strategic asset. One of the most critical technology choices manufacturers faces is whether to implement custom manufacturing software development or opt for off-the-shelf software. Both options come with unique advantages and trade-offs and understanding them can help your business align technology with long-term growth and operational excellence.

This blog walks you through key factors to consider, offering a clear decision-making framework to guide your plant’s digital transformation.

Off-the-shelf software refers to pre-built applications designed to meet the needs of a broad range of businesses. These are readily available, tested, and come with standard functionalities such as inventory management, production tracking, quality control, and reporting.

Pros

Cons

"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

Future-Proof Your Plant with Custom Manufacturing Software

Gain end-to-end visibility, seamless system integration, and scalable control with tailored solutions built around your unique operations.

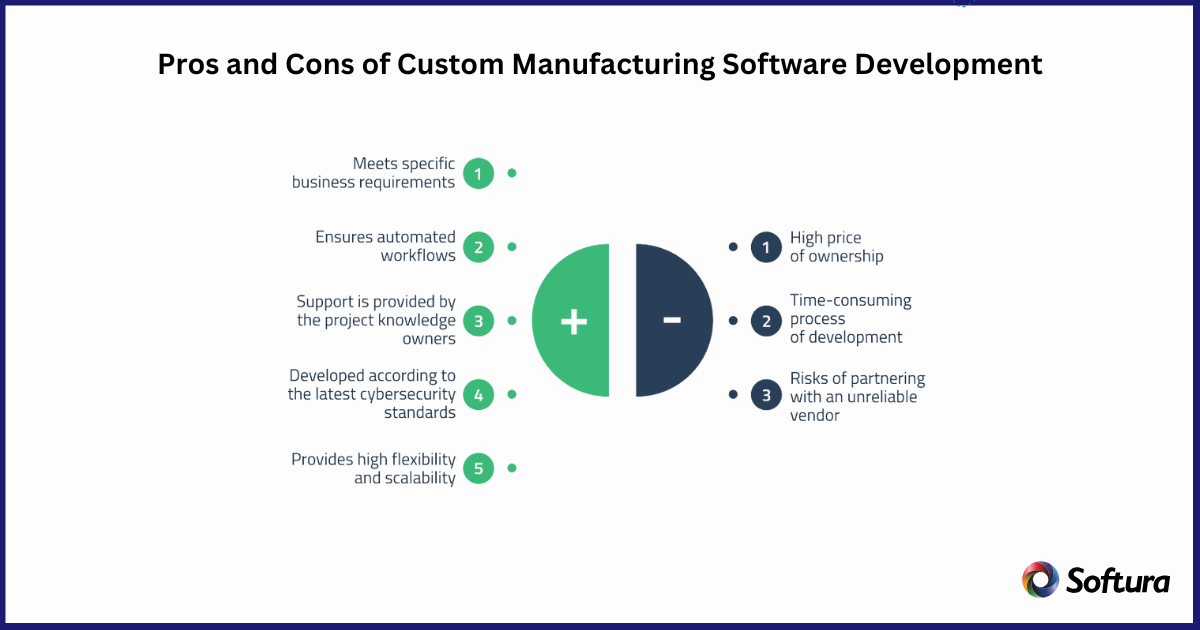

Custom software is developed specifically for your plant's unique workflows, business rules, and integration needs. It allows you to tailor every feature to match your operational structure—whether you’re running a smart factory, handling complex supply chains, or managing specialized production environments.

Pros

Cons

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Choosing the right software begins with understanding how well each option aligns with your plant’s goals, processes, and future growth.

If your plant operates with highly standardized processes and minimal customization, off-the-shelf software may meet your needs. However, if your manufacturing involves multiple production lines, custom formulations, or complex automation systems, custom manufacturing software development is often a better fit.

Do you need your manufacturing software to work with legacy equipment, ERP systems, or third-party applications like CAD tools or inventory platforms? Off-the-shelf software might offer basic integrations, but custom solutions ensure seamless, bidirectional connectivity tailored to your tech stack.

Custom software grows with you. If your plant plans to scale production, expand to new geographies, or adopt advanced technologies like AI/ML or predictive maintenance, a custom-built system allows you to incorporate those features without costly workarounds.

While off-the-shelf software may appear cheaper upfront, hidden costs like additional licenses, integration plugins, or forced upgrades can increase your TCO. Custom software development may have a higher initial investment but tends to offer a better return over time through reduced manual work, fewer bottlenecks, and greater automation.

If time is a critical factor and your needs are generic, an off-the-shelf solution may offer the speed you require. But if your software needs to align with a phased rollout or match a strategic transformation roadmap, custom development offers the flexibility to build incrementally.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Here are some key areas where custom manufacturing software services can make a big difference in your plant.

Plants aiming to implement Industry 4.0 principles—including real-time sensor data, digital twins, or automated workflows—benefit immensely from custom solutions built around specific IoT infrastructures.

For industries with strict regulatory environments (e.g., pharmaceuticals, aerospace), custom software enables detailed traceability, custom audit logs, and compliance reporting that off-the-shelf tools often lack.

If your plant uses proprietary manufacturing methods or hybrid production models, custom software ensures that the system adapts to your processes—not vice versa.

Custom software enables real-time tracking of production metrics—such as throughput, cycle times, and machine efficiency—tailored to your specific KPIs. You can configure alerts for downtime, defects, or abnormal patterns that are unique to your production logic, helping supervisors act instantly to reduce scrap and delay.

For plants dealing with high variability in raw material availability, shipping delays, or multi-location coordination, a custom solution can automate supply chain workflows, integrate with supplier systems, and adjust production schedules dynamically based on inventory, logistics, and demand signals—something generic software often can't accommodate deeply.

Custom software allows you to build user experiences specific to different roles—floor operators, maintenance staff, supervisors, or plant managers. This not only improves usability but ensures data security and operational control by providing access to only relevant tools and dashboards.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Choosing between off-the-shelf software and custom manufacturing software depends on your business goals and operational complexity. Use this framework to make an informed choice:

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Some manufacturers adopt a modular strategy, integrating off-the-shelf components for basic functions (like HR or payroll) while using custom manufacturing software development for core operations like MES, machine monitoring, and process automation. This hybrid approach balances cost and flexibility while accelerating digital maturity.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

There’s no one-size-fits-all answer. But as plants shift toward smart manufacturing, real-time analytics, and integrated operations, custom solutions are becoming less of a luxury and more of a necessity. Off-the-shelf tools still play a role—especially for standard processes—but custom manufacturing software development gives forward-thinking manufacturers the control, agility, and innovation edge they need in 2025 and beyond.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

At Softura, we specialize in custom manufacturing software development tailored to meet the evolving needs of modern plants. Whether you're optimizing production lines, integrating IoT sensors, or enabling AI-driven forecasting, our team combines decades of industry experience with cutting-edge technology stacks.

From initial consultation to deployment and support, we partner with you to build solutions that scale with your vision. Our software is designed to streamline operations, enhance quality control, and deliver actionable insights—all while integrating with your existing infrastructure.

Explore how Softura can help transform your plant with purpose-built manufacturing software.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Outgrow Generic Software—Build for What Sets You Apart

Discover how Softura’s custom solutions empower smart factories, real-time monitoring, and industry-specific compliance.