"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

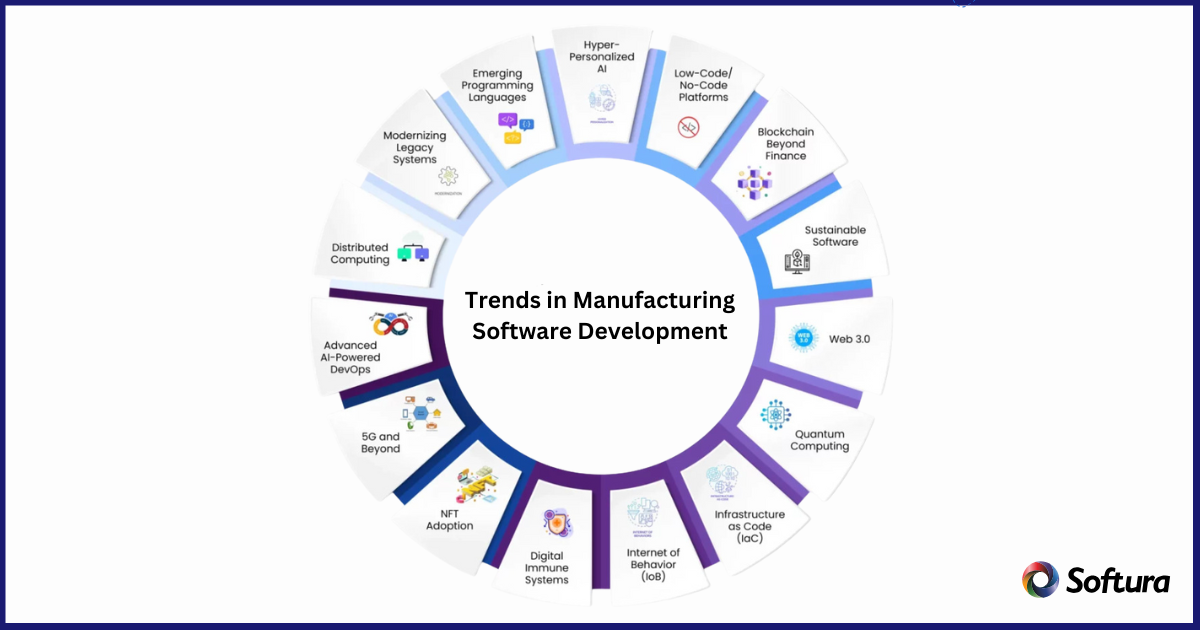

The manufacturing sector is experiencing a profound shift fueled by rapid technological advancements. As Industry 4.0 evolves, key trends are transforming the industry, enhancing efficiency, sustainability, and adaptability to market needs. Incorporating AI, cloud computing, and embedded systems into manufacturing software is no longer optional; it is essential. These technologies streamline operations while maintaining high-quality production.

Discover how manufacturers can adopt AI and other innovations cost-effectively and securely without disrupting workflows. In this blog, we examine the top tech trends shaping manufacturing software development in 2025, offering insights into their practical applications.

The manufacturing industry is harnessing advanced technologies to boost efficiency and optimize asset performance through data-driven solutions. Below are key tech trends shaping manufacturing software development in 2025, with AI as a central driver.

5G technology, extending beyond telecommunications, is transforming manufacturing software by providing high-speed, reliable networks. It enables seamless communication between production lines, robots, and IoT devices in smart factories, enhancing automation and remote equipment control. Known as "Green 5G" for its energy efficiency, it promotes sustainability and operational resilience, making it a vital component of AI-driven manufacturing software solutions.

Smart applications combining AI, IoT, and robotics are revolutionizing manufacturing software development. These solutions streamline maintenance, predict equipment needs, and optimize asset performance, thereby minimizing the need for manual intervention. By enabling advanced automation, they enhance operational efficiency and adaptability to dynamic production demands.

AI-powered preventive and predictive maintenance leverages IoT and cloud analytics to monitor equipment in real-time. By analyzing data on performance and environmental conditions, these systems predict potential failures, reducing unplanned downtime. Companies like PepsiCo and Colgate-Palmolive utilize these technologies to preempt machinery issues, ensuring production continuity.

Cloud-based platforms are critical for managing manufacturing data and delivering real-time insights that enhance equipment reliability. These systems collect, store, and analyze data to support dynamic maintenance strategies, reducing costs and downtime. Cloud-driven software solutions enable manufacturers to respond swiftly to market changes, providing scalability and flexibility.

Embedded systems are advancing manufacturing software by delivering secure, tailored solutions for automation and IoT integration.

Customized Systems: Expertise in embedded systems drives digital transformation by providing secure and efficient software solutions tailored to business needs.

Firmware Development, Verification, and Testing: Bare-metal programming optimizes software by directly controlling hardware. Comprehensive firmware support ensures reliability.

Embedded Software and Hardware Development: Custom hardware platforms address scalability and compliance challenges.

Real-Time Operating Systems (RTOS) Deployment: Tailored RTOS solutions enhance responsiveness and meet real-time constraints for manufacturing applications.

Edge computing software processes data on the factory floor, thereby reducing latency and enabling real-time decision-making. These platforms analyze IoT sensor data locally, enabling applications such as quality control. Developers create scalable edge solutions that integrate with AI, optimizing performance while minimizing cloud dependency.

Augmented reality (AR) software enhances human-machine collaboration by providing real-time guidance and support. Developers build AR platforms for training and maintenance, overlaying digital instructions on physical equipment. Integrated with AI, these systems adapt to user actions, improving productivity.

Sustainability-focused software optimizes resource usage, reducing environmental impact. Developers create platforms that monitor energy consumption and material waste, using AI to suggest efficiencies. These systems track resource lifecycles, aligning with 2025's green priorities.

"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

Manufacturing software powered by AI, cloud platforms, and embedded systems delivers transformative benefits, including:

AI-driven monitoring software enables real-time tracking and analysis of equipment health. Machine learning algorithms detect anomalies, allowing systems to address issues autonomously.

Real-time data transforms into actionable insights with advanced software, improving equipment performance and enabling proactive maintenance planning.

Predictive modeling software anticipates equipment failures, facilitating timely interventions. These tools optimize asset management and improve ROI.

Software that analyzes trends refines production planning and promotes predictive maintenance. Advanced algorithms enable precise machinery control.

AI, machine learning, and IoT technologies elevate productivity by optimizing workflows and leveraging 5G for rapid device connectivity.

Automated data collection software streamlines processes, enhancing data accuracy and security while reducing human error.

Real-time inventory tracking software delivers enhanced visibility, accurate forecasting, and cost management. Integration with IoT and cloud ensures comprehensive oversight.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

In 2025, manufacturing software development will be revolutionized by digital transformation. The trends mentioned above enhance efficiency, sustainability, and resilience. Advanced software enables real-time decisions, secures connected systems, and streamlines production.

By adopting these innovations, industry leaders can achieve operational excellence and meet evolving market demands.

Contact us to find out how we can enhance production efficiency with tailored software innovations.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

See How These Trends Apply to Your Business

Talk to our experts about how AI, edge computing, and smart systems can drive real transformation in your manufacturing operations—without disrupting what works.